Such previously popular and gradually forgotten roofing material, such as shingles, was found in the central and northern regions. It was made from aspen, due to the widespread occurrence of the material. This coating has served for decades. It was used on peasant houses and wooden churches. Today, the old fashion is gradually returning, but due to the lack of specialists able to make shingles, the material is expensive and considered to be elite. If you like its appearance, but you don’t have enough money, then you can consider the alternative offered by the modern construction market - imitation of shingles. It will cost much less. Or you can try to make and lay the roof of shingles with your own hands.

Content

Material Features

Among the advantages of shingles as a roofing material are the following:

- It is resistant to temperature extremes and high humidity.

- Thanks to the installation method, a ventilated space remains, which prevents the formation of condensate.

- Environmental friendliness. Along with the naturalness of the material, one can note the non-chemical nature of its production.

- Lack of need of coloring. To change the color, special impregnations are used, which not only are able to give the desired shade, but also extend the service life.

- Shingles prevent freezing or overheating of the roof. Coverage allows the building to breathe.

- The material is not susceptible to decay and destruction due to the presence of resins in the wood, as well as the density and high saturation of tannins.

- Noise isolation, which is provided by the relief structure of the plates.

- Water resistant due to grooves that form during fiber splitting.

- Aesthetics. The appearance of such a roofing over time can only become more interesting.

- Durability - subject to proper installation.

Manufacturing methods

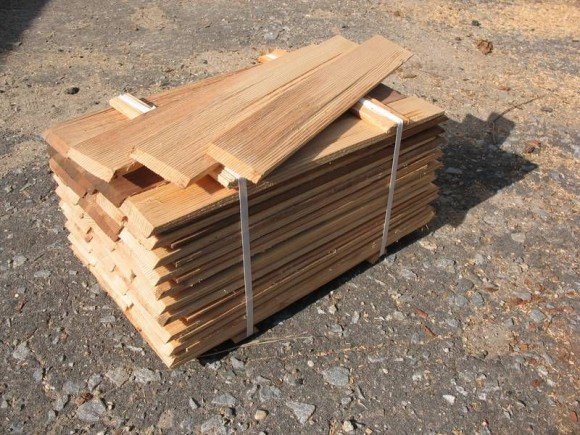

Shingle is a thin plate of wood. Their average thickness is 3-8 mm. with a width of 8-16 cm. and a length of 35-45 cm. Traditionally, shingles were made of pine. As the material, you can also choose spruce or larch. For the manufacture of material suitable trees with a small diameter. An important condition is the presence of smooth trunks, suitable for cutting blockheads without knots. At the same time, their length should be in the range of 40-45 cm. The core on the chocks is excluded due to the high risk of cracking. This can be done by splitting the little block in half or 4 parts, after which the core is cut down. The remaining part must be split into thin plates - this will be the shingle. Material can be harvested at any time of the year except winter. Before starting work, do not forget to remove the bark.

The bark left on the details will lead to the premature formation of rot on the roofing material.

Industrial manufacture of shingles also exists. Its principle is to cut the log into logs having double length. After they produce a timber blank with a width corresponding to the future shingle. The last stage is sawing the beam into the final material. But its drawback in large length is about 80 centimeters. Therefore, the use of such shingles is possible only on a roof with a large area. For small roofs, before starting work, it will be necessary to saw it, thereby reducing the service life. Chipped shingles will last longer due to the natural breakdown and preservation of fibers.In order not to lose the integrity of the material, for its manufacture it is necessary to use the old method of splitting. It involves the use of a special plow - a knife that has two handles. Note that this work is too meditative. And it can take a lot of time to prepare the material on the roof of a large area. But there is a solution - the “wave” machine. This is the simplest tool that will help in the production of shingles.

In 1939, the Soviet inventor Glazunov V.N. received a patent for a machine for the production of shingles in an industrial way.

Antique do-it-yourself machine

DIY machine manual:

- For work, you need a log with a length of three to four meters with a diameter of 12-16 cm. In it you need to drill a hole with a diameter of 3 mm. It is done at a distance of 20 cm from the end.

- In the hole made, it is necessary to insert a metal king pin and provide it with freedom of movement. Its length should be chosen in such a way as to ensure the fastening of the log in a wooden block.

- From the side of the end face on which the hole is made, the knife is fastened. This should be done by stepping back one meter from the edge. A bracket acts as a knife, the length of which should be equal to 60 cm. It is set at an angle so that it is possible to remove the required thickness from the chunks.

- A handle 40 cm long is knocked down on the reverse side of the log. It will help to move the log during operation.

- It is important for comfortable work to ensure the correct length and width of the wooden block. These parameters should be selected in such a way that, provided the block is laid under the shingles, the “waving” does not come off.

Do not work with a dry tree. The material must be soaked or boiled in boiling water for 30 minutes before work. For this, an iron barrel is suitable. Digestion is used for coniferous wood. All work is done per day.

Shingling

Some roof requirements for such roofing material:

- Bias. It should not be less than 15 degrees.

- Crate. It is better to use solid or with a pitch of not more than 10 cm. Due to the light weight of wooden boards, bars with a cross section of 5x5 cm are suitable as material, as well as poles having a diameter of 6 to 7 cm.

Material laying:

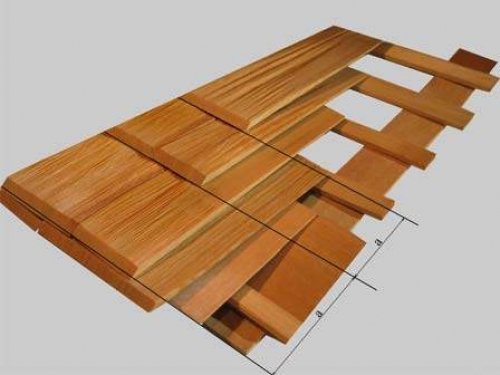

- It is produced in several layers. Their number varies from one to five. In the presence of two layers, the laying of the plates is overlapped by half. If there are three layers, then by 2/3, for four layers - 3/4, and for five overlays it is 4/5 of the previous shingle.

Two-layer coating is used on non-residential buildings, but from three to five are suitable for residential.

- The waterproofing layer can be laid in the form of roofing material. It is placed on a crate. But according to ancient traditions, this stage of work can be excluded so as not to interfere with the roofing “breathing” and to avoid the formation of rot.

- Installation of shingles begin from below, from the eaves overhang, heading towards the ridge.

- The roof outlets must be additionally covered with boards having a width of 35-40 cm, and the number of shingles should be increased by one relative to the entire roof.

- For fastening the material, special dracochnal nails are used, having a length of 4 to 6 cm. Before starting work, they must be boiled in drying oil.

- If shingles are produced by the cleavage process, this forms a plate in a special way. When it is bent, the fibers are raised, which are called "pins." When laying the first row, they must be positioned so that the resulting "pins" are located on top. For the remaining rows, they are deployed on the inside of the roofing.

- With the presence of endov, the process of work is complicated. It will require the laying of an additional layer of shingles, as well as the installation of auxiliary battens.

Modern imitation

In the modern construction market you can find an amazing variety of roofing materials designed to mimic shingles.. Thanks to advancing technologies, they produce, for example, copper shingles. It is worth noting that such material is not very similar to its ancestor. Copper plates are made of diamonds, squares or fish scales of different sizes with a thickness of less than 1 mm. On them are the "ears" intended for attachment to the crate. At a cost they are similar to hand-made wooden plates. Although among the advantages it should be noted fire resistance, ease of installation, a variety of colors. But the disadvantages can be noise and low environmental friendliness.

American manufacturers have a special collection of shingles made of shingles. Along with this, you can find polymer imitations made of PVC, resins, mineral additives. They are most similar to their historical counterpart in color, size and shape.

The price of roofing shingles

In appearance, the shingles are divided into chipped and sawn. The first will cost more.

Pricing options:

- plate thickness and length;

- raw materials used - valuable wood species can significantly affect the cost;

- degree of processing and impregnation.

Average price for 1 sq.m. will be from 2.5 to 3 thousand rubles.

But you can always try to make shingles with your own hands - however, for this you will need some experience and tools. On the other hand, such a roof will certainly be pleasing to the eye and will surprise others.

Alas, no comments yet. Be the first!