Viking metal tile is a modern roofing material, which is the result of a collaboration between the Russian company MetallProfil and the Swedish company AkzoNobel.

Both companies occupy the top positions in building ratings. When developing a polymer coating for the Viking metal roof, all the most modern technologies were applied and the Russian climate was taken into account.

The polymer is made in Sweden. The whole process is fully controlled by specialists. The basis of the coating is polymer F-670, which is an innovative substance manufactured by AkzoNobel. In fact, Viking is an improved matte polyester.

Pay attention to the purchase of a roof, since cases of fraud are not rare. On AkzoNobel products, in particular on the Viking metal tile, on the inside (not front) side of the sheet, there is a company marking. In appearance, the metal tile has a slightly rough surface. If you are offered a smooth glossy roofing material, claiming that it is a Viking coating, then they are trying to deceive you.

Content

Advantages of Viking Metal Roofing

Thanks to some technical changes in production, the following quality indicators of the Viking metal tile were achieved:

- Resistance to ultraviolet radiation. The coating retains saturated color for many years;

- Metal Viking weight 1m? is about 5 kg;

- Resistance to temperature fluctuations. The coating is able to withstand sudden changes in temperature; The minimum temperature is -45 ° C, maximum + 120 ° C. At the same time, without losing its properties;

- Resistance to environmental influences. The tile is not subject to the influence of weather changes, it will not suffer from strong winds or hail;

- Viking roof tiles retain anticorrosion properties for up to 40 years;

- In order for the material to have high-quality protection from the effects of the atmosphere, which can lead to corrosion, oxidation, corrosion of the layers, the method of hot galvanization is used;

- Convenient parameters and low weight of the Viking metal tile make it possible to carry out installation easily, without technical difficulties;

- The term of operation is more than 40 years;

- Beautiful appearance. Due to the matte surface, the metal tile looks more voluminous, which visually approximates its appearance to natural clay tiles;

Thus, the metal Viking reviews has the most positive. Consumers have absolutely no complaints about the quality of this roofing material.

Color spectrum

To date, the Viking metal tile in four shades is presented on the market of roofing materials:

- green;

- chocolate brown;

- Gray;

- red brown.

It may seem that the color scheme is not too diverse. However, in reality, these shades are enough to pick up the roof to the building of any architectural design.

Metal Viking: material characteristics

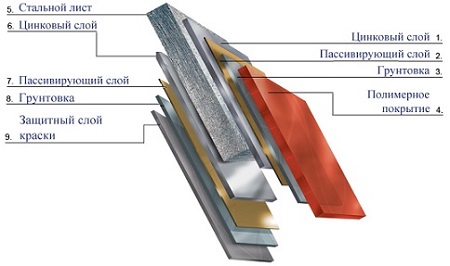

The metal tile Viking has the following structure:

- a metal sheet;

- anticorrosion coating;

- primer;

- polymer coating.

Metal Viking technical specifications:

- Zinc coating is applied to a metal sheet with a volume of 140 g per 1 m ?;

- The thickness of the metal sheet is either 0.4 mm or 0.45 mm.This makes the roof easier and more flexible;

- Spraying polymer from polyester - 35 microns;

- Profile height - 39 mm;

- Designed for pitched roofs, the slope of which is at least 12 °.

It is environmentally friendly, meets the basic European requirements for the environmental friendliness of the product. This is confirmed by the availability of quality certificates.

To protect the product during transportation, a special film is applied to the surface.

The fastening of the roof elements is carried out using self-tapping screws, in the deflections of the wave. Average consumption per 1 m? is 6-8 pieces.

Viking metal tile sheet sizes are as follows:

- length 1 m 18 cm;

- width 35 cm.

Production of metal Viking

The metal Viking is made on the latest high-tech equipment.

The production process is as follows. Metal in special machines is rolled to a uniform thickness. After stage by stage all layers of protective coatings, the main polymer, are applied. Then the sheets are sent to the installation, where profiling takes place. The final step is the packaging of roofing material.

The process of cutting metal viking

There are no special restrictions on how to cut a Viking metal tile. All standard tools for cutting metal can be used: an electric jigsaw, manual or electric shears for metal, a hacksaw, an electric saw with a special disc.

The manufacturer of metal tiles Viking strongly discourages the use of a grinder. The fact is that when using a grinder, the edge of the metal sheet heats up, the protective coatings melt and lose their properties. As a result, the edge remains open for moisture to enter. Rust or corrosion can form, which, one way or another, will lead to damage to the tile sheet as a whole.

Places of cuts, scratches, scuffs and other damage to the protective coating can be painted over from a spray can or with a brush, this does not matter.

Useful tips

In order for the metal tile to serve more than one year, but for a very long time, it is necessary to apply the following tips in practice:

In the process of erecting a roof and installing metal tiles, a certain amount of chips is formed on the surface. It must be very carefully removed from the surface of the roof.

Do not allow any scratches or chips on the tiles. It must be remembered that their presence can lead to damage to the material. In case of damage, they must be primed and painted over.

Twice a year, a visual inspection of the roof should be carried out. If surface damage is detected, corrective action should be taken.

Remember that the metal sheets of the Viking tiles are relatively thin, which is why the erection of the roof should be done very carefully: do not bend or drop the sheets, do not walk on them, avoid contact with sharp objects.

If it is necessary to store metal tiles on the street, the sheets are folded either in stacks, separated by wooden beams, or under a slope. This is necessary so that the water does not accumulate and has the ability to evaporate and drain.

Manufacturers guarantee that if during the installation and operation of the roof all technical requirements are met, the service life of the Viking metal tile will be at least 40 years.

Price range

AkzoNobel roofing products attract not only with high quality, but also with a rather flexible pricing policy. In comparison of quality and cost, the Viking metal tile has no analogues. Price for 1 m? varies from 200 to 350 rubles. At the same time, you buy not just reliable material, but peace of mind and confidence in the future.

Thus, we can say that the Viking metal tile has high strength and reliability.The roofing material from the Swedish manufacturer is able to last several decades, without ever causing any inconvenience. A wide color spectrum makes it possible to choose a roof to your liking, making it possible to translate any desire into reality.

Alas, no comments yet. Be the first!