The use of flat slate as a roofing material is quite common today.

Therefore, here we will focus on this particular coating, its main parameters: dimensions, weight, marking, etc. Slate is flat, the dimensions of which are very different and depend directly on the specific building, it is used for residential buildings and for commercial buildings. In addition to roofing, this material can be used in other areas, namely:

- Facing buildings inside and out;

- Production of "dry couplers";

- Installation of wall coverings according to the Sandwich method;

- Protections for balconies, loggias;

- Installation of structures with a wide profile;

- Use in agriculture, gardening.

Content

Production, types and features

Sheets of this slate are produced using the following components: water, asbestos, Portland cement. The reinforcing mesh formed by asbestos fibers evenly distributed in the cement solution significantly increases the level of strength of the material, its impact strength, as well as tensile strength.

The quality characteristics and size of a slate flat, like any other material, depend on the equipment and technology in the production where it is made.

The mechanical characteristics of asbestos depend on such factors:

- Quality - fiber diameter and average length;

- Content;

- Chemical composition;

- Mineralogical composition;

- Fineness of grinding;

- Uniform distribution of asbestos fibers in cement.

Flat asbestos-cement slate can be painted with silicate paints or phosphate binders. The presence of a paint layer will give it a more perfect appearance, prevent premature destruction, increase the level of resistance to atmospheric phenomena, which will extend the life of the slate.

It is also important that such protection will significantly reduce the amount of asbestos released.

Sheets of this slate are used mainly to cover roofs with a slope exceeding 12 degrees. Slate weight (1 sq.m.) = 10-14 kg.

There are such types of asbestos-cement sheets:

- Flat slate, dimensions: length = 2.5, 3 and 3.5 m, width = 1200 or 1500 mm, thickness = 6, 8, 10 mm;

- Tile (scales), dimensions: 40X60 mm;

- 5-wave slate - impractical due to large overlaps;

- Slate 6-wave, dimensions: 54/200, width: 1125 mm. Of all the species, the thickest;

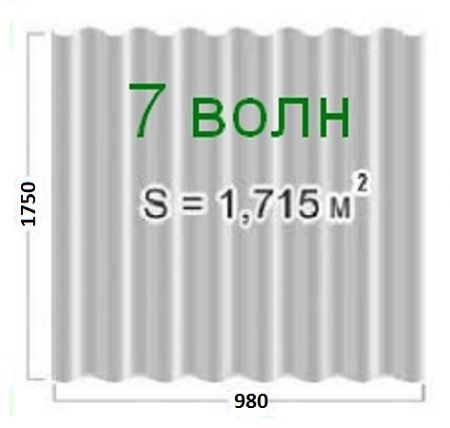

- Slate 7-wave, dimensions: length = 1750 mm, width = 980 mm. One of the most popular types;

- Slate 8-wave dimensions: length = 1750 mm, width = 1130 mm.

GOST Standards

Flat slate, according to GOST, is marked with alphanumeric characters. They are decrypted in this way:

LP-P - pressed flat sheet.

LP-NP refers to an unpressed flat sheet.

The numbers indicated in the marking reflect the size, that is, the length, width, thickness of the flat slate. At the end of such an inscription, GOST is necessarily indicated.

The standard asbestos-cement slate, the sheet size of which may be different, has a rectangular shape.

In addition to a rectangular shape, GOST 18124-95 puts forward such requirements:

- The deviation in a rectangular shape is not more than 5 mm;

- Deviations from the plane of not more than 4 mm are for a pressed sheet, not more than 8 mm for an unpressed one;

- Deviations in size - not higher than 5 mm.

As for the sizes of sheets of flat slate, the following are the main ones in Russian industry:

- Sheet length = 3600 mm, width = 1500 mm, sheet thickness = 8 mm; 10mm;

- Sheet length = 3000 mm, width = 1500 mm, sheet thickness = 8 mm; 10 mm;

- Sheet length = 2500 mm, width = 1200 mm, sheet thickness = 6.8 mm; 10 mm.

As already mentioned above, the slate is also divided into pressed flat and non-pressed flat. At the same time, the pressed slate is flat, the weight of which significantly exceeds the weight of the unpressed, has a high level of technical characteristics.

Here are their main differences:

- Bending strength (pressed - 23 MPa, unpressed –18 MPa);

- Impact strength (pressed - 2.5 kJ / m2, unpressed - 2.0 kJ / m2);

- Ability to withstand low temperatures (pressed - 50 cycles of alternate freezing / thawing, 25 - for unpressed);

- Residual strength (pressed - 40%, unpressed - 90%).

When buying a batch of flat slate, pay attention to the marking. On each batch according to GOST 18124-95, a label should be affixed where it indicates: name of the company that produces the slate, batch number, production date, thickness, sheet sizes, type designation of sheets (pressed, unpressed).

The maximum package weight according to GOST 18124-95 = 5 tons.

The total height of packages stacked on top of each other should be approximately 3.5 meters. Slate sheets need to be stored in a stack on gaskets or pallets.

Transportation, as well as storage of sheets of asbestos-cement flat slate, is carried out in packaged form. In this case, use pallets or wooden gaskets.

When buying, the weight of the slate should be taken into account, since the calculation during the construction of the building depends on it.

Slate wave sheet parameters

Given the standards of GOST, the dimensions of the wave slate are defined as follows:

- Length - 1750 mm;

- Width depends on the number of waves;

- Thickness = 5.8 mm (profile = 40/150) and 6 mm; 7.5 mm (for profile 54/200).

Slate Width happens:

- 980 mm is an 8-wave slate;

- 1130 mm is a 7-wave slate;

- 1125 mm is a 6-wave slate.

The first digit in the designation of the profile is the wave height, the second is the wave step in mm.

As for the weight, for example, the weight of the wave slate 8 will depend on the thickness and will be 23-26 kg.

When choosing an asbestos-cement slate, pay attention to the weight of the slate sheet! It should be a guide for choosing a rafter system of a certain thickness!

If you want to calculate the usable area of a sheet, then it is calculated very simply:

When overlapping sheets per wave = 0.8 of the nominal area.

With two waves = 0.7 of the nominal area.

At the same time, remember: the overlap of slate sheets is made not only in the horizontal rows of the roof, but also in the vertical ones too!

We give an example: if the size of a 7-wave slate = 980 x 1750 mm (1.715 sq. M), then its usable area will be 1.14 sq.m.

In addition to adjusting the GOST dimensions of the slate sheet, there are certain requirements for shaped parts. Often, nodes and all kinds of joining of the roof are made of galvanized iron. There are also parts made of asbestos-cement material.

GOST identifies those:

- Skate overlapping;

- Skate overlapping;

- Skate overlapping simplified;

- Skate overlapping simplified;

- Tray;

- Isosceles corner;

Their length can be as 1125, and 1130 and 1750 mm. The overlapping wave height is 46 or 60 mm. It already depends on what size slate is 8-wave (for 7 it is similar), 6 or 5 wave.

Shaped details are very important for a slate roof, since this material is absolutely not flexible and has a specific relief.

Wave bitumen slate

And another, relatively new type of slate is wave bitumen or ondulin. It is more modern due to its technical side. Ondulin roofing is easy to process and allows independent construction.

The plastic wave slate also belongs to such a simple form in terms of installation and construction. It is used so far in cases of sheltering small buildings: arbors, terraces, greenhouses.

So, slate can be of different types, sizes, different weights. When planning buildings, these characteristics and nuances are very important - the reliability of buildings and their quality performance will depend on them.

We hope you find our slate information useful!

Alas, no comments yet. Be the first!